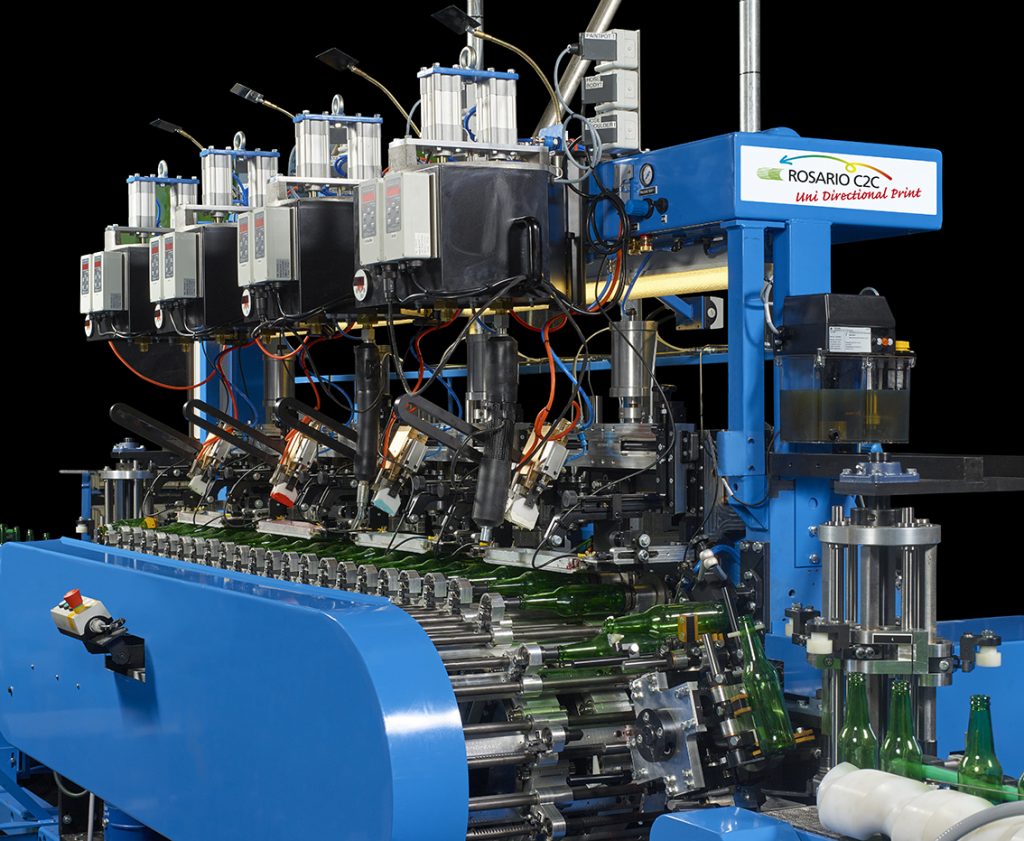

Paint Dispensing Systems

to automate the decoration process

Are your bottle decorating machines still equipped with manual paint feeding systems? With our innovative paint dispensing technology you can now raise productivity, quality and safety of your bottle decoration line.

ROSARIO’s new automatic and semi-automatic enamel paint dispensing systems offer a range of high precision, automatic or semi-automatic dispensing tools for multi or single colour decoration, including the use of modern UV-inks.

You can either mount a new system onto or on the outside of the machines you have in use, or decide to upgrade to the fully integrated ROSARIO Auto Paint Dosing System (APDS) in compliance with the latest CE Standards.

We shall be glad to advise you on the possibilities that fit your situation the best.

1. Fully paint dispensing systems (CE standard)

A. Rosario Automatic Paint Dosing System (APDS) meeting CE standards

Net capacity inner pot : 2,5 liter

Length dispensing tube max. 2,6 meter

- Auto paint feed means no interruption of production

- Improved and consistent print quality resulting from optimised feed rate

- Auto temperature control ensures no overheating and wastage

- Extended delivery hose allows pots to be sited for ease of access

- Quick change of inner pot

- Independent control of hose-and pot temperature

- System can be retrofitted

- System is easily cleaned

B. Rosario semi-automatic Paint Dosing System (PDS) meeting CE standards

Same technical specifications as the Rosario APDS, however the dispensing is activated manually by pushing a button on the panel of the pot.

2. Conventional paint dispensing systems

A. Rosario Semi –automatic paint heating and dispensing system

- Paint heating system for enamels and organic paints where pots are mounted above the screens. Paint is dispensed into the screens through heated tubes.

- Temperature of pots and tubes are adjustable and controlled

- Dispensing is effected pneumatically by pushing a button, which is mounted on the pot.

B. Rosario Automatic paint heating and dispensing system

- Paint heating system for enamels and organic paints, where pots are mounted above the screens. Paint is dispensed automatically into the screens through heated tubes. The temperature of the pot and tube can be set and the paint in the pot is controlled automatically.

Innovation

In bottle printing

The latest technology for high speed decoration is inkjet direct-on-glass printing.

Special Offers

Some clients trade in machines for new.

We refurbish them for resale in special deals.

Under full warranty.

UPDATES

ROSARIO C2C is an active participant at leading trade conferences and exhibitions. Find white papers, presentations, reviews and events here.